All Modules

We are helping build tomorrow’s diverse technician pipeline with an open, online and accessible learning environment for all. View a complete listing of modules below.

New Course Recently Added

Environmental Control Systems

Designed to partially fulfill the Airman Certification Standards requirements set out for an Aviation Mechanic career pathway for the Airframe Curriculum Subjects for Aviation Maintenance Technician Schools.

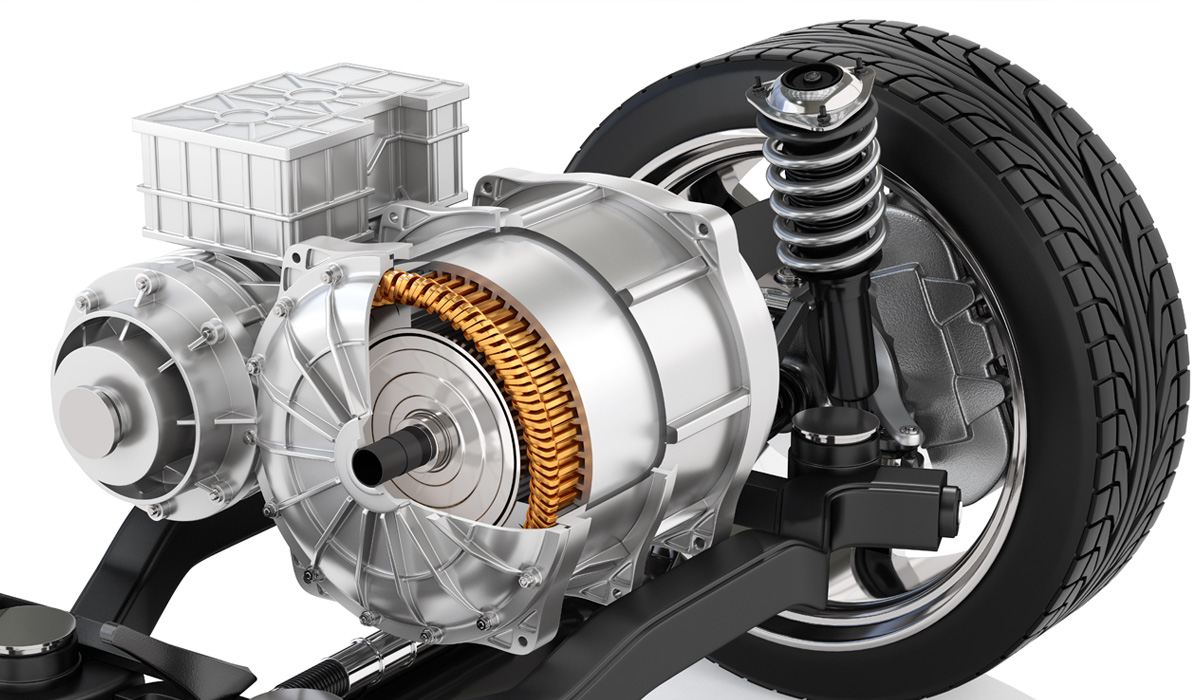

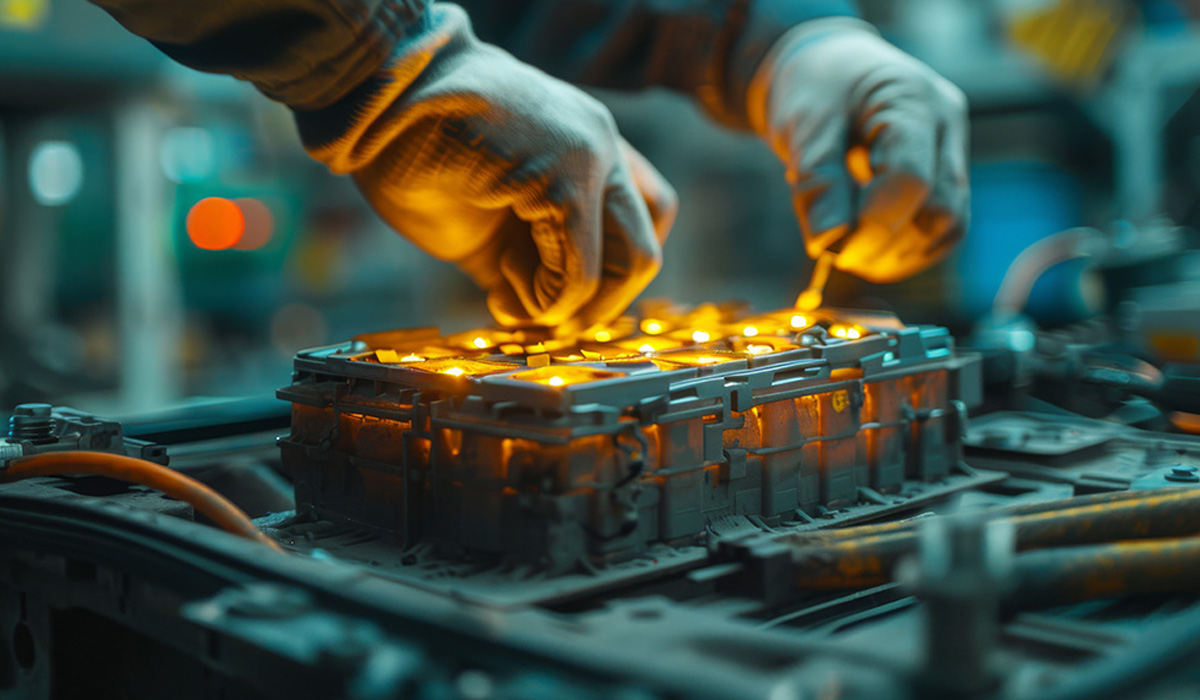

Battery Electric Vehicles (BEVs)

This pathway equips learners with the training necessary to service and manufacturing battery electric vehicles (BEVs). It offers two programs: Service Technician and Manufacturing Technician.

Program: Battery Electric Vehicle Service Technician

Overview

Exploring Electric Vehicles (EVs): Industry Importance and Historical Evolution

Module

Overview and Comparisons of Vehicle Types in the Automotive Industry

Key Electric Vehicle (EV) Basic Terminology

Fundamentals of a Battery Electric Vehicle (BEV)

Overview of Battery Technologies in Electric Vehicles (EVs)

End-of-Course Test and Survey

Overview

Personal Protective Equipment (PPE)

Battery Electric Vehicle (BEV) Safety and Standards

End-of-Course Test and Survey

Overview

Introduction to Electrical Fundamentals

Electrical Applications in a Battery Electric Vehicle (BEV)

Introduction to Electric Motors

Motors in BEVs

End-of-Course Test and Survey

Overview

Battery Chemistry & Construction

Battery Management Systems (BMS)

End-of-Course Test and Survey

Overview

Automotive Vehicle Connectivity

Autonomous Drive Systems

Advanced Driver Assist Systems (ADAS)

End-of-Course Test and Survey

Overview

Introduction to On-Board Diagnostics (OBD)

Fundamentals of Battery Electric Vehicle (BEV) Features, Monitoring, and Diagnostics

Accessing On-Board Diagnostics (OBD) Data in Battery Electric Vehicles (BEVs)

Benefit of On-Board Diagnostics (OBD) for Battery Electric Vehicle (BEV) Owners and Technicians

End-of-Course Test and Survey

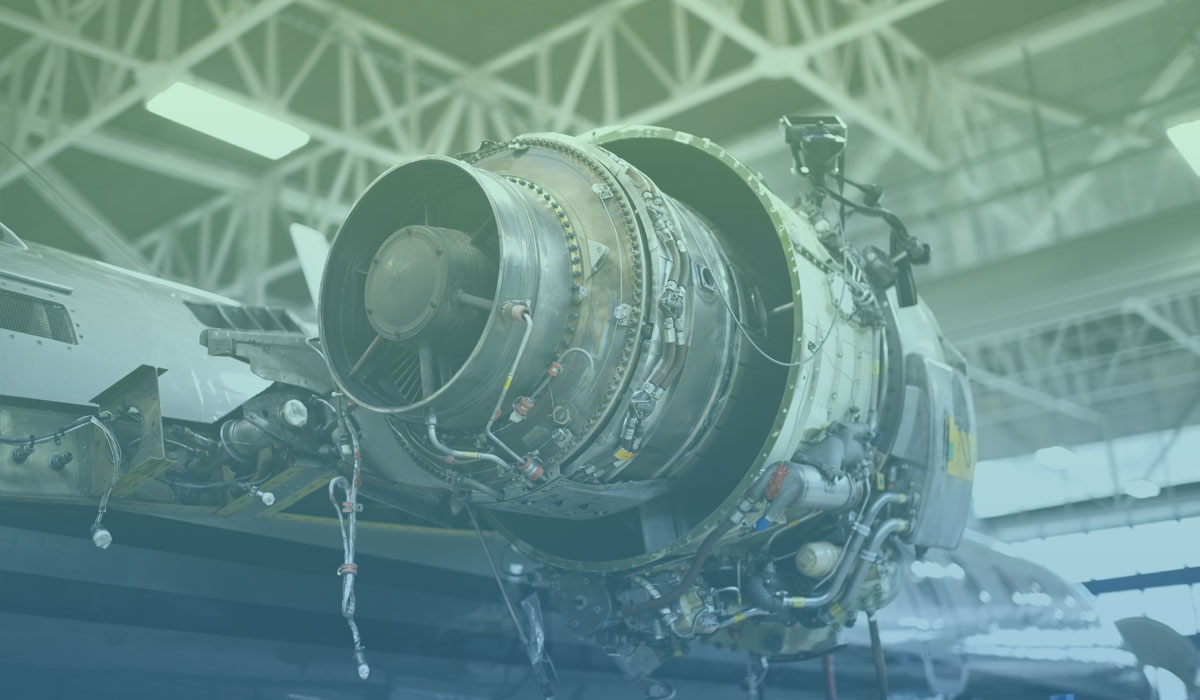

Federal Aviation Administration – Airman Certification Standards

This pathway equips learners with the training necessary to meet the Federal Aviation Administration (FAA) Airman Certification Standards (ACS) and become an Aviation Mechanic (AM). It offers three programs: General, Airframe, and Powerplant. The General program serves as a prerequisite for the other two and is recommended as the first step. It covers all the knowledge, skills, and risk mitigation elements outlined in the ACS’s general section. Upon completing this learning path, participants can pursue FAA mechanic or repairman certification through on-the-job experience or by finishing the required coursework at one of the 190 FAA-certificated aviation maintenance schools.

Program: Aviation Mechanic General

Overview

Fundamentals of Electricity

DC Circuits

AC Circuits

Circuit Measuring Instruments

Electronics and Logic

Generators, Motors, and Alternators

End-of-Course Test and Survey

Overview

Computer Graphics and Aviation Drawings

Illustration Methods and Meanings of Symbols and Lines

Reading, Interpreting and Storing Drawings

End-of-Course Test and Survey

Overview

Weight and Balance Control

Procedures for Weighing an Aircraft

Loading and Extreme Conditions

Graphs, Records and Other Considerations

Review

Overview

Rigid Fluid Lines

Flexible Hose Fluid Lines

End-of-Course Test and Survey

Overview

Aircraft Metals and Non-Metallic Materials

Inspection Techniques

Aircraft Hardware

Welding and Soldering

Review

Overview

Shop and Flight Line Safety and Fire Protection

Tiedown Procedures and Ground Movement of Aircraft

Servicing and Fuel Servicing of Aircraft

End-of-Course Test and Survey

Overview

Types and Forms of Corrosion

Inspection and Removal of Metal Corrosion

Processes and Materials Used in Corrosion Control

End-of-Course Test and Survey

Overview

Maintenance, Inspections, and Mechanic Privileges

Performing and Recording Maintenance and Inspections

Products, Parts and LSA

Maintenance Ethics and Human Factors

End-of-Course Test and Survey

Overview

Matter, Energy and Simple Machines

Stress, Motion, Heat, Pressure, and Gas

Fluid Mechanics, Sound, and the Atmosphere

Theory of Flight

End-of-Course Test and Survey

Overview

General Purpose Hand Tools

Metal Cutting Tools

Layout and Measuring Tools

End-of-Course Test and Survey

Program: Aviation Mechanic Airframe

Overview

Landing Gear Structure

Wheels and Tires

Landing Gear Brake Systems

End-of-Course Test and Survey

Overview

Hydraulic Principles

Hydraulic Components

Pneumatic Systems

End-of-Course Test and Survey

Overview

Cabin Environmental Systems

Cabin Climate and Oxygen

End-of-Course Test and Survey

Co-DREAM OER Open Textbooks

This pathway offers textbook materials for Co-DREAM OER (Collaborative Development of Robotics, Mechatronics, and Advanced Manufacturing Open Educational Resources). This initiative, funded by the US Department of Education, aims to develop textbooks focused on robotics, mechatronics, and advanced manufacturing processes. A diverse group of scholars and graduate students from various regions have created these resources, which are designed for advanced robotics courses in associate, undergraduate, and graduate programs.

Robotics

Foundational Robotics

Introduction to Robotics

Kinematics

Mobile Robots

Trajectory Generation, Path Planning, And Control

Human-Robot Collaborative Manufacturing

Robotics

This pathway provides training for several programs (High School, Associate and Bachelor) for robotics in advanced manufacturing.

Program: High School Track

Program: Associate Track

Overview

Control Systems

Robot Maintenance and Troubleshooting

Case Study and Future of Robots

Review

Overview

Process Modeling

Part Production

Joining Techniques

Smart Manufacturing Systems

Manufacturing Automation Systems

Review

Program: Bachelor Track

Overview

Introduction to Robotics

Building a Universal Robot Deployment Team

Improving Performance of Universal Robots

Review

Overview

Universal Robotics

Programming and I/O Connections

UR Safety and Troubleshooting

Review

Overview

Process Modeling

Part Production

Joining Techniques

Smart Manufacturing Systems

Manufacturing Automation Systems

Review

Manufacturing Skill Standards Council

This pathway will equip learners with the foundational technical competencies necessary for high-demand, higher-wage, higher-skill jobs in advanced manufacturing set forth by Manufacturing Skill Standards Council (MSSC).

Program: Certified Production Technician

Overview

Concepts of Safety and Health

Safety Organizations and Regulations

Communicating Safety in the Manufacturing Environment

Safety at Facilities

Environmental Control and Noise

Material Handling & Electrical Safety

Machinery, Hand Tool and Equipment Safety

Poisonous Chemicals & Flammable Materials

Personal Protection and First Aid

Ergonomics in the Workplace

Exam

Overview

Quality Management Systems

Quality Control

Continuous Improvement

Quality Inspections

Corrective Actions

Lean Manufacturing Principles

Root Cause Analysis

Introduction to Six Sigma

GD&T

Blueprint Reading

Popular Measuring Instruments

Exam

Overview

Introduction to Manufacturing and Production

Properties of Engineering Materials

Engineering Materials

Product Manufacturing

Production Process

Machining Operations

Tool & Equipment Operation: Lathes

Special Processing

Manufacturing Systems

Production Components

Controlling & Documenting Production

Packaging and Distributing Products

Manufacturing Support Systems

Exam

Overview

Introduction to Maintenance

Reliability of Systems

Planned Preventive Maintenance

Predictive Maintenance Techniques

Maintenance of Electrical Systems

Maintenance of Pneumatic Systems

Maintenance of Hydraulic Systems

Maintenance of Basic Mechanical Systems

Maintenance of Specialty Production Systems

Maintenance Programs

Maintenance Information Systems

Economics of Maintenance

Exam

Additional Courses

Enhance your skillset with these specialized, non-program-specific courses.

Overview

Bioengineering

Chemical Engineering

Civil Engineering

Electrical and Computer Engineering

Environmental and Biosystems Engineering

Industrial Engineering

Materials Science and Engineering

Mechanical Engineering

Course Summary

Introduction and Overview

Exploring Advanced Manufacturing

Manufacturing Career Clusters

A Hands-on Virtual Experience

Next Steps

Course Survey

Overview

Introduction to Electricity

Electric Circuits

Electromagnetism

Basic Passive Circuit Components

Fundamentals of Solid State Devices

Solid State Devices and Circuits

Energy Storage and Circuit Protection

Power Generation and Transmission

DC Machines

AC Fundamentals

AC Machines

Three-Phase Power Systems

Exam

Overview

Introduction to Metrology

Popular Measuring Instruments

Industrial Instrumentation: Temperature & Pressure

Industrial Instrumentation: Force, Torque & Flow

Electrical Measuring Instruments

Exam

Overview

Reading Comprehension

Locating Information

Critical Thinking / Analytic Skills

Basic Math

Mathematical Applications

Introduction to Computing

Computer Application and Skills – Word

Computer Application and Skills – PowerPoint

Computer Application and Skills – Excel

Basic Employability

Professional Work Ethic

Review